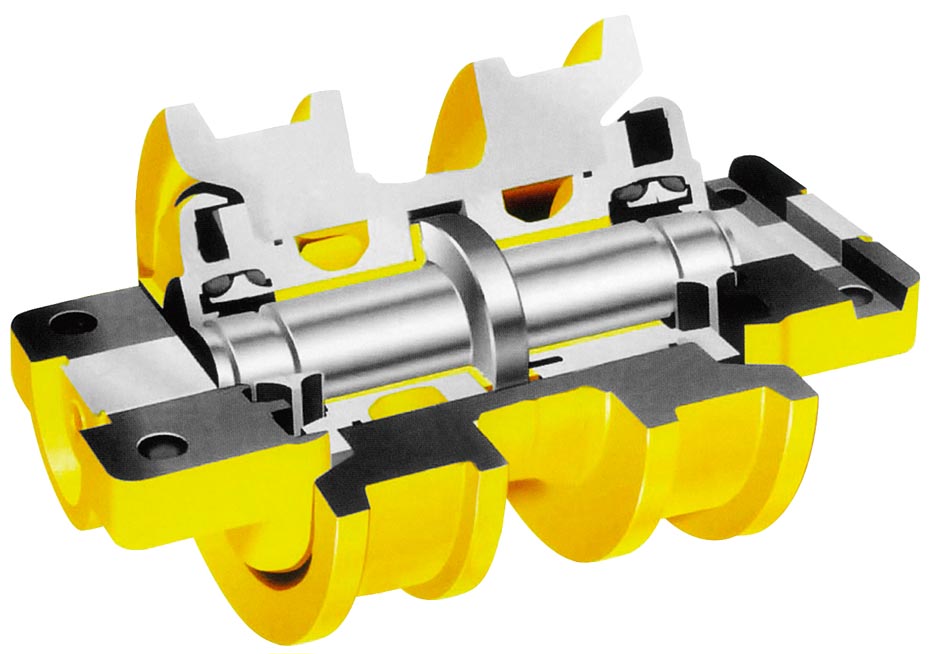

The structure of the bottom roller is mainly divided into the wheel body, the supporting wheel shaft, the shaft sleeve, the floating oil sealing, and the end cover.

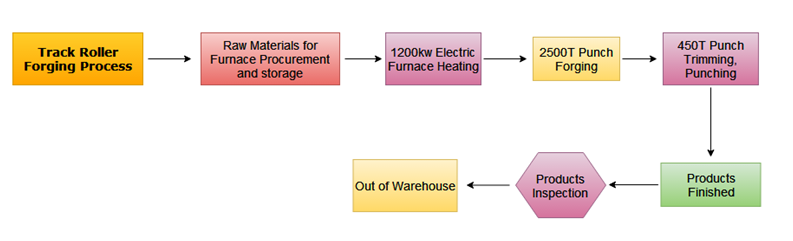

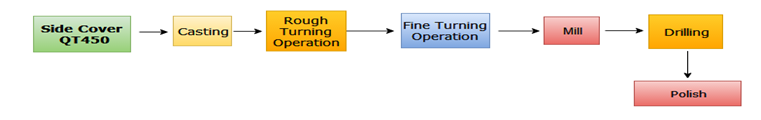

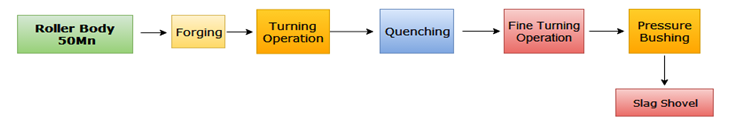

To make high quality track roller mainly depends on the performance of its steel. The material of the roller body is generally 50Mn, 40Mn2, (MN: synonymous with manganese element). The manufacturing process is divided into casting or forging, machining, and then heat treatment. After the surface of the wheel is quenched The hardness reaches HRC55~58 to increase the wear resistance of the wheel surface.

The machining accuracy requirements of the supporting rollers are relatively high. Generally, CNC machine tools are required for machining to meet the requirements.

There are more materials of 40Mn2, and the hardness reaches about HRC52.

What should be paid attention to during the operation of the paver roller?

1. During the operation of the paver, the distance traveled at a time should not be too long, and the speed should not be too fast; the support wheels will generate high temperature during long-term fast driving, and the lubricating oil will leak out due to dilution. Cause damage to the supporting wheels. Once a roller is found to be damaged, it should be replaced in time, otherwise the adjacent rollers will also be accelerated wear due to excessive force. When replacing the support rollers, the wear condition should be considered. If the degree of wear is small, it can be replaced alone, otherwise all should be replaced, so as not to accelerate the wear of the new replacement roller.

2. Because the screed on the paver is too heavy, the center of gravity of the whole machine is deviated, so the rear rollers of the paver bear the greatest force during the working process, which is easy to damage, and the paver can be damaged if it is damaged. When walking, the screed will go up and down, which will cause the paving road to be wavy, which directly affects the smoothness of the road.

Problems prone to paver rollers:

1. Roller body wear. The reason for this situation is that the steel used is unqualified or the hardness of the material during heat treatment is low, and the wear resistance is lacking.

2. Oil leakage. The bearing wheel shaft is constantly rotating through the shaft sleeve, and the wheel body needs to be lubricated to make it smooth, but if the sealing ring is not good, it is easy to cause oil leakage, so that the shaft and the shaft sleeve are easy to wear when they are not smooth. The formed product cannot be stopped using.

There are several reasons for the oil spill?

1. Unqualified floating oil seal

2. The roundness of the product sleeve is not enough

3. Insufficient gloss of fulcrum

4. Gear oil is not up to standard

5. The problem of machining dimensional tolerances, etc. will cause oil leakage in the rollers

JINJIA MACHINERY is a leading business of large scale in engineering machinery with a wide range of undercarriage parts on lower roller, upper roller, sprocket, idler and track chains and track shoes and good reputation since 1990.

Post time: Oct-23-2021