Working environment of a bulldozer is harsh, so it is crucial to use and maintain the undercarriage parts properly. Based on years of bulldozer service experience, I would like to share some tips on the use of undercarriage parts。

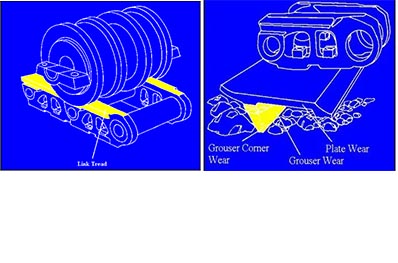

1.Track Link assy

Bulldozers move by tracks, and the motor's traction force is significant. As each track chain segment has a certain length, and the sprocket rim is in a gear shape, there is a polygon effect during movement. When the entire track shoe is parallel to the ground, the radius is smaller, while one side of the track plate in contact with the ground results in a larger drive radius, causing the bulldozer's movement speed to be inconsistent and producing vibrations. Improper use of equipment, uneven road surfaces, changes in tension force, and the presence of foreign objects such as soil and sand on the track chain segments can cause resonance, resulting in jumping of the individual segments, accompanied by noises. When severely, this can accelerate the wear of the undercarriage components and even cause the tracks to derail.

2. Carrier Rollers, Track Shoe,Sprocket Rim and Top Rollers

The materials used in undercarriage parts of a bulldozer are alloy steel with added wear-resistant materials that are forged and cast. While there is a protective film on the metal surface that has undergone heat treatment, improper operation, improper tensioning of tracks, or the presence of objects can wear off any metal protective film, ultimately accelerating the wear of the undercarriage components.

Usage precautions: ● Avoid turning in place on concrete roads. ● When crossing areas with a significant height difference, such as trenches, avoid operating the steering. When crossing obstacles or areas with a large height difference, make make the machine move straight to avoid the track plate from falling off. ● Regularly adjust the track tension force based on the "Driver's Manual.

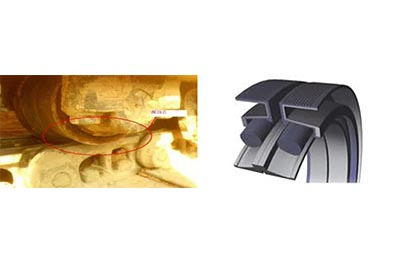

3.Floating Oil Seal

The walking motor and reducer, carrier rollers, idlers, and track rollers inside the bulldozer require gear oil for lubrication. The floating oil seal is a non-contact seal that prevents oil leakage and does not leak during normal use. However, when excessive foreign objects such as mud and sand accumulate from the outside, they can enter the seal and cause damage, resulting in oil leakage. In addition, prolonged walking of the bulldozer can cause the oil temperature to rise and the floating oil seal to age, eventually resulting in oil leakage

Precautions: ● Thoroughly clean the machine's body of mud and water to prevent damage to the seal from dirt and water droplets entering the seal. ● Park the machine on a hard, dry surface. ● Timely remove foreign objects from the undercarriage components. ● Replace the floating oil seal in a timely manner according to the driver's manual to prevent oil leakage.Finally, please use the correct operating methods for equipment operation and perform regular maintenance on the equipment. Ensure that original CAT bulldozer parts are used for replacement to extend the equipment's service life.

Post time: Mar-15-2023