Wear law of track shoes

During normal operation, the track pin rotates slowly backward in the pin hole, the two wear evenly, the pin hole gradually becomes larger, and the pin gradually becomes thinner. If the operation is improper, such as high-speed turning, abrupt start, or entering muddy water, weeds, etc. to block the pins, it will cause the left and right sides of the track shoes to be over-stressed and sag, and the pins will be deformed and bent. Rotation, the pin and the pin hole become sliding friction, and the friction part is limited to a small part of the contact surface, the pin is gradually ground into a crank shape, and the pin hole also becomes an ellipse.

The increase in the pin hole also causes the track pitch to lengthen (the pitch is the center distance of the holes at both ends of the track shoe), so the track shoe and the drive wheel grind each other, the track shoe is worn through, and the drive wheel teeth are blade-shaped. According to the measurement, when the pitch is changed from 174 mm to 184 mm, the opening width of the driving gear teeth is changed from 87 mm to 97 mm, and the normal rolling meshing is completely destroyed at this time.

Since the track shoe pitch is elongated, it also causes the rollers to jump during walking, which accelerates the wear of the track shoe runway. When the subsidence of the runway is greater than 4 mm, it should be repaired.

The wear of the guide part of the track shoe is mainly caused by the deviation of the track, the severe deformation of the track shoe, and the excessive axial shaking of the roller and guide wheel.

The common scrapped track shoes are severely worn or worn through the meshing part with the drive wheel.

Repair of track shoes

The wear of the track shoe mainly has two parts: the raceway surface and the track pin hole. It is very simple to repair. After the raceway is worn, a groove sags, and when the depth does not exceed 2~3 mm, it can be directly surfacing and repaired. When the wear is deep, steel bars of different sizes can be filled in the grooves according to the specific conditions, and then welded from all sides. The pin hole should be restored to the original size and the center position of the original hole after grinding. For this purpose, cut the worn pin hole, insert a standard size pin, then heat it to about 800 ℃, and then roll up the edge of the ear. Add a semi-circular iron plate to the outside of the incision and weld it firmly with electric welding. The track shoes thus repaired can last for more than 100 shifts.

Substitute steel for track shoes

The track shoes of tracked vehicles are generally made of high manganese steel with a history of nearly a hundred years of use. This is because high manganese steel has a prominent feature, that is, it undergoes impact hardening under the action of impact load, making it form a surface layer that is both hard and wear-resistant, while still maintaining the toughness and plasticity of its inner layer. However, high manganese steel is used as a track shoe, which is often damaged early due to cracks, inverted teeth and deflection during use, and has a low service life. In order to overcome this shortcoming, a low-alloy high-strength steel 30SiMnMoV(Ti) steel, which is based on domestic resources and is easy to produce, has been developed. It has been successfully used to replace high-manganese steel to manufacture track shoes.

processing methods

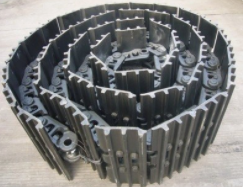

The processing technology of the track shoe of the profile is generally: the use of profile cutting, drilling (punching), heat treatment, straightening, painting and other processes; the track of the bulldozer is single-reinforced, and the general paint color is yellow; It is three-rib, and the paint color is black. The material purchased for the profile is generally 25MnB, and the final heat treatment hardness of the material is HB364~444.

Post time: Aug-26-2022