Excavator, also known as excavation machinery, is an earth-moving machine that uses a bucket to excavate materials above or below the bearing surface and load it into a transport vehicle or unload it to a stockyard. This time we conducted a detailed analysis of the excavator walking system and common faults.

1. Excavator walking system

(1) Features of the walking device

Because the traveling device has the two functions of support and operation of the hydraulic excavator, the traveling device of the hydraulic excavator should meet the following requirements as far as possible:

1. It should have a large driving force, so that the excavator has good passing performance, climbing performance and steering performance when walking on wet or soft or uneven ground.

2 Under the premise of not increasing the height of the running gear, the excavator has a larger ground clearance to improve its off-road performance on uneven ground.

3. The traveling device has a larger support area or a smaller grounding specific pressure to improve the stability of the excavator.

4. When the excavator goes down the slope, the phenomenon of sliding and overspeed sliding will not occur, so as to improve the safety of the excavator.

5. The overall dimensions of the walking device should meet the requirements of road transportation.

The walking device of hydraulic excavator can be divided into two categories: crawler type and tire type according to the structure.

(2) Crawler and tire excavators

1. Crawler type walking device

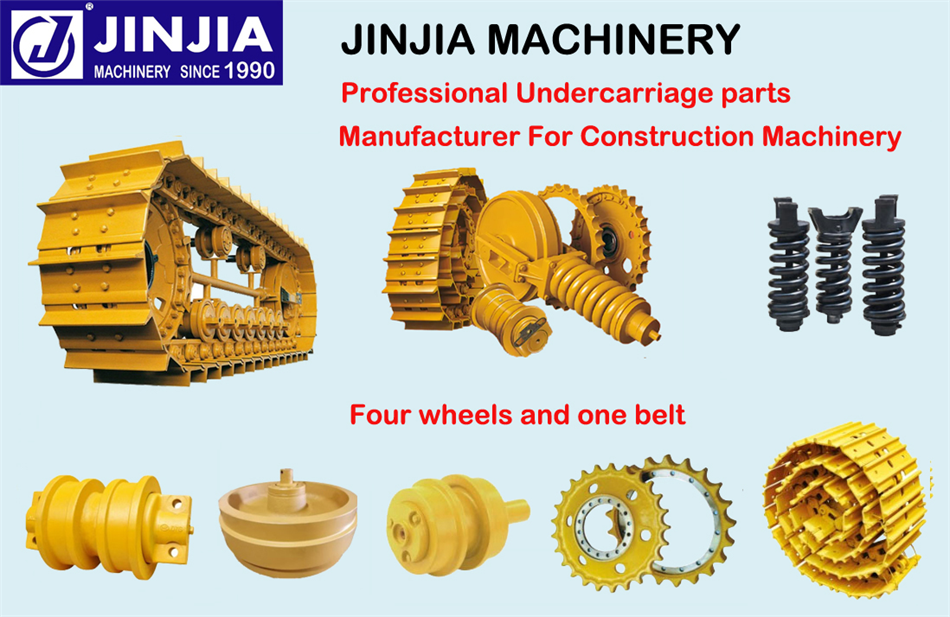

The crawler type traveling device is composed of “four wheels and one belt” (Idler,top roller,track roller,sprocekt rim,track link assy), tensioning device and buffer spring, traveling mechanism, traveling frame, etc. When the excavator is running, the driving wheel drives Yin and grounding Yin (supporting Yin) on the tight side of the track to generate a pulling force, in an attempt to pull the track out of the track roller, because the track under the track wheel has sufficient adhesion to the ground. , to prevent the pull-out of the track, forcing the drive wheel to roll the track, and the guide wheel to lay the track on the ground, so that the excavator runs forward along the track track by the roller.

2. Wheel-type walking device. There are many structural types of tire-type hydraulic excavator walking device. There are wheeled tractor chassis that use standard automobile chassis, but tire-type hydraulic excavation with slightly larger bucket capacity and higher working performance requirements adopts special tire-wheeled chassis running gear.

1) No outriggers, all wheels move, the turntable is arranged in the middle of the two axles, and the two axles have the same wheelbase. The advantages are that the outriggers are omitted, the structure is simple, the operation is convenient on narrow construction sites, and the maneuverability is good. The disadvantage is that the steering axle has a large negative cut when the excavator is walking, and the steering operation is laborious or a hydraulic assist device needs to be installed. Therefore, the traveling device of this structure is only suitable for small tire hydraulic excavators.

2) Double outriggers, all-wheel drive, the turntable is biased to one side of the fixed axis (rear axle). Its characteristics are: lighten the load of the steering axle and make the steering operation easier; the outriggers are installed on the side of the fixed shaft to ensure the stability of the excavator during operation. This type of walking device is mostly used in small tire-type hydraulic excavators.

3) Four legs, single-axis drive, the turntable is far away from the center. Its characteristics are: good stability. The disadvantage is: driving on the soft ground will form three wheel pits, the driving resistance will increase, and the lateral stability of the three fulcrum chassis is poor. Therefore, this type of walking device is only suitable for small excavators.

4) Four legs, all-wheel drive, the turntable is close to the side of the fixed axle (rear axle). Its characteristics are: easy to operate, low requirements on the ground.

Two common fault analysis and troubleshooting

1. The engine speed drops

First, test the output power of the engine itself. If the output power of the engine is lower than the rated power, the cause of the failure may be poor fuel quality, low fuel pressure, incorrect valve clearance, a certain cylinder of the engine does not work, fuel injection timing is wrong, fuel The setting value of the quantity is incorrect, the air intake system is leaking, the brake and its joystick are faulty, and the turbocharger is coke.

2. If the output power of the engine is normal, you need to check whether it is incense because the flow rate of the hydraulic pump does not match the output power of the engine. The speed of the hydraulic excavator is inversely proportional to the negative pressure during operation, that is, the product of the flow rate and the output pressure of the pump is a constant, and the output power of the pump is constant or approximately constant. If the pump control system fails, the optimal load matching state of the engine, pump and valve in different working conditions will not be achieved, and the excavator will not work normally. Such failures should start with the electrical system, then check the hydraulic system, and finally check the mechanical transmission system.

3. The excavator is powerless

Weak excavation is one of the typical faults of excavators. Weakness in excavation can be divided into two types: one is weakness in excavation, the engine does not hold the car, and the load is very light:

The second type is weakness in excavation. When the boom or stick is extended to the bottom, the engine is seriously choked or even stalled.

1. The excavation is weak but the engine does not hold the car. The size of the digging force is determined by the output pressure of the main pump, and whether the engine is braked depends on the relationship between the oil pump’s absorption of the rotary cabinet and the output torque of the engine. The fact that the engine does not hold up indicates that the oil pump absorbs a small rotary cabinet and the engine load is light. If there is no obvious abnormality in the working speed of the excavator, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked.

2. If the measured value of the overflow pressure is lower than the specified value, it indicates that the setting value of the over-cut relief valve of the hydraulic circuit of the mechanism is incorrect, which causes the mechanism to overflow prematurely and work weakly. Then the machine can be adjusted by turning the adjusting screw.

3. Excavation is weak, and the engine stalls. The engine stall indicates that the absorption torque of the oil pump is greater than the output torque of the engine, causing the engine to overshoot. This kind of failure should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system returns to normal function, the engine stall phenomenon disappears, and the digging force returns to normal.

4. Common faults in the excavation process, some common faults that often occur in the excavator in the construction operation, such as: the excavator runs off-track, the reason may be that the walking distribution oil seal (also known as the center rotary joint oil seal) is damaged: hydraulic cylinder Rapid leakage may mean that the safety relief valve is not tightly closed, or the cylinder oil seal is seriously damaged, etc.

5. Daily maintenance of the excavator In order to prevent the failure of the excavator, it is necessary to pay great attention to the maintenance of the excavator during daily use.

Daily maintenance includes checking, cleaning or replacing the air filter element: cleaning the inside of the cooling system: checking and tightening the track shoe bolts: checking and adjusting the track back tension: checking the intake air heater: replacing the bucket teeth: adjusting the bucket clearance: checking the front window Cleaning fluid level: Check and adjust the air conditioner; clean the floor in the cab; replace the crusher filter element (optional).

There are still many faults encountered by excavators in daily work. Here is just an introduction to the maintenance methods of several common types of faults, and the purpose is to reduce the occurrence of faults, which is very important for the daily maintenance of excavators.

Post time: Jul-27-2022