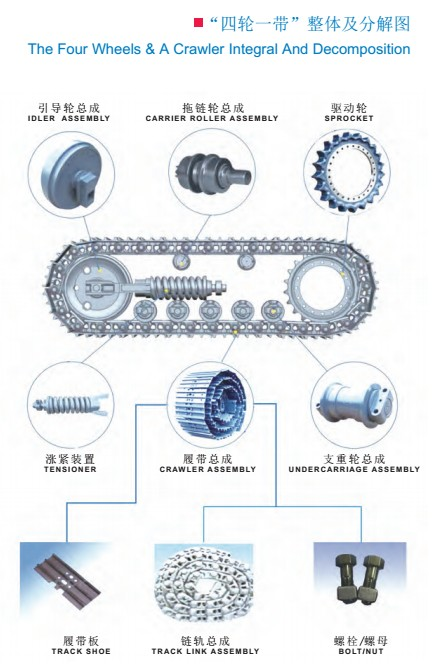

The four wheels in the “four-wheel belt” of the excavator refer to the Track Shoe, Sprocket, Track Roller, and Idler, and the belt refers to the track. They are directly related to the working performance and walking performance of the excavator, and their weight and manufacturing cost account for one-fourth

The Structure diagram of four wheels and one belt of excavator

Introduction to the four-wheel and one-belt structure of the excavator

1. Track Shoe

Track Shoe classification: There are two types of integral type and combined type.

The integrated track is a track plate with meshing teeth, which tends to mesh with the drive wheel, and the track shoe itself becomes the rolling track of wheels such as rollers. In particular

I would like to remind everyone: Quanzhou Hongda Machinery is an expert in the production of four-wheel and one-part components of excavators. The company has been working hard to improve and serve customers for 30 years since its establishment in 1990.

Track features: easy to manufacture, but fast wear.

At present, the multi-purpose combination of excavators is characterized by small pitch, good revolving, and fast walking speed of excavators. long lasting. The materials used for the track shoes are mostly rolled plates with light weight, high strength, simple structure and low price. There are several kinds of single tendons, double tendons, and three tendons.

2. Sprocket

Introduction to the drive wheel: The power of the hydraulic excavator engine is transmitted to the track through the travel motor and the drive wheel. It is required that the drive wheel and the track chain of the track are properly meshed, the transmission is smooth, and the track can still be well stretched due to wear and tear of the pin sleeve. mesh. The drive wheels are usually located at the rear of the excavator travel gear. According to the structure, it can be divided into: integral type, split type, according to the pitch, it can be divided into: equal pitch, unequal pitch

3. Track Roller

Introduction to the rollers: The function of the rollers is to transmit the weight of the excavator to the ground. When the excavator is driving on an uneven road, the rollers will be impacted by the ground, so the rollers are subjected to large loads and poor working conditions. , often in dust, and sometimes immersed in muddy water, so a good seal is required.

Features of rollers: mostly supported by sliding bearings. And dustproof with floating oil seal. Generally only need to add butter once during an overhaul, which simplifies the daily maintenance of the excavator.

4. Idler

Introduction to the Idler: Idler is used to guide the track to revolve correctly and prevent it from deviating and deviating from the track.

Most excavators also function as rollers. This can increase the contact area of the track to the ground and reduce the ground specific pressure. The wheel surface of the idler is made of smooth surface, and there is a retaining arm ring in the middle as a guiding function, and the ring surfaces on both sides support the rail chain. The smaller the distance between the idler and the nearest roller, the better the guiding. Material: 40, 50 steel, or 35MN, cast, quenched and tempered, hardness HB230-270

Key points of the Idler: In order to make the idler work and prolong its life, the radial run-out of the wheel facing the center hole should be less than or equal to 3MM, and it should be correctly centered during installation.

5. Carrier Roller

The role of Carrier Roller is to hold the crawler upwards, so that the crawler has a certain degree of tension.

Post time: Jun-29-2022