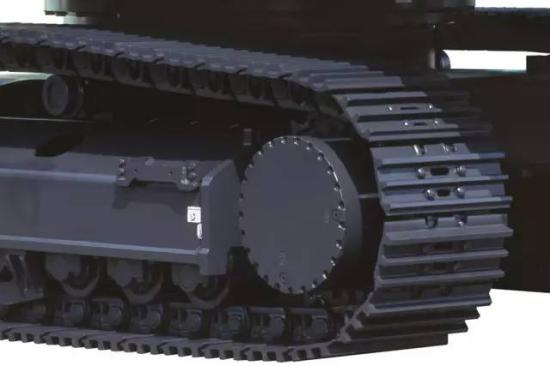

Many people have complained about problems like oil leakage from the supporting wheels, damage to the carrier rollers, and inconsistent tension of the tracks, which are all related to the

four-wheel-track of excavators. The four-wheel-track plays a crucial role in the performance and movement of excavators, and proper maintenance and repair are crucial for ensuring fast and

efficient movement. Here are some maintenance and repair methods related to the four-wheel-track:

track roller

The track rollers should be kept away from mud and water as much as possible. After each day of work, the excavator should be lifted on one side, and the drive motor should be used to

remove any dirt, stones and other debris from the tracks. During winter, it is important to keep them dry to prevent the water from freezing to ice overnight and causing damage due to

contact with the seals. Damaged supporting wheels can cause various problems, such as slow and uneven movement, and deviation from the track.

.Carrier rollersThe carrier rollers are located above the X-frame and are responsible for keeping the tracks straight. Damage to the carrier rollers can cause the tracks to fail to stay on

track. The carrier rollers are filled with lubricating oil, and if they leak, they must be replaced. They should be kept away from mud and water, and the X-frame should be free from dirt

and stones to ensure smooth roller rotation.

Idler roller

The idler rollers are located at the front of the X-frame and include a tension spring. To minimize abnormal wear of the tracks, the guide wheels should be kept at the front during work and

movement. The tension spring also helps to absorb shocks caused by the road surface during work.

Sprocket rim

The sprocket roller are located at the rear of the X-frame and have no shock-absorbing function. The front movement of the drive wheels can cause abnormal wear and tear on the drive

sprockets, tracks, and X-frame. The drive motor shield can protect the motor and prevent dirt from entering and damaging the oil hose, which can corrode the joints. Therefore, the shield

should be opened regularly to clean the dirt.

Track shoe

The tracks shoe consist of track plates and chain joints, which come in standard and extended versions. Extended tracks are used for wetland work, and standard tracks are used for

earthwork. In a mine site, the tracks are the most vulnerable and tend to get stuck with stones, causing the plates to bend or crack after extended use. Over-tightening the track tension

can also cause early wear and tear on the chain joints, sprockets, and guide wheels. Therefore, the track tension should be adjusted according to the different working conditions.

Post time: Mar-13-2023