Maintenance of undercarriage parts for excavator

For excavator maintenance work, the owner will pay more attention to the hydraulic system or engine. After all, the core parts are maintained, the machine can work smoothly and earn more income.

But the undercarriage parts seem to be the part that my uncle doesn’t care for my grandma. If it breaks, replace it with a new one, saving trouble and time. I don’t know that the replacement cost of excavators has increased sharply! In fact, everyone has done the following maintenance precautions for the undercarriage parts, and it is not a problem to save tens of thousands of yuan a year.

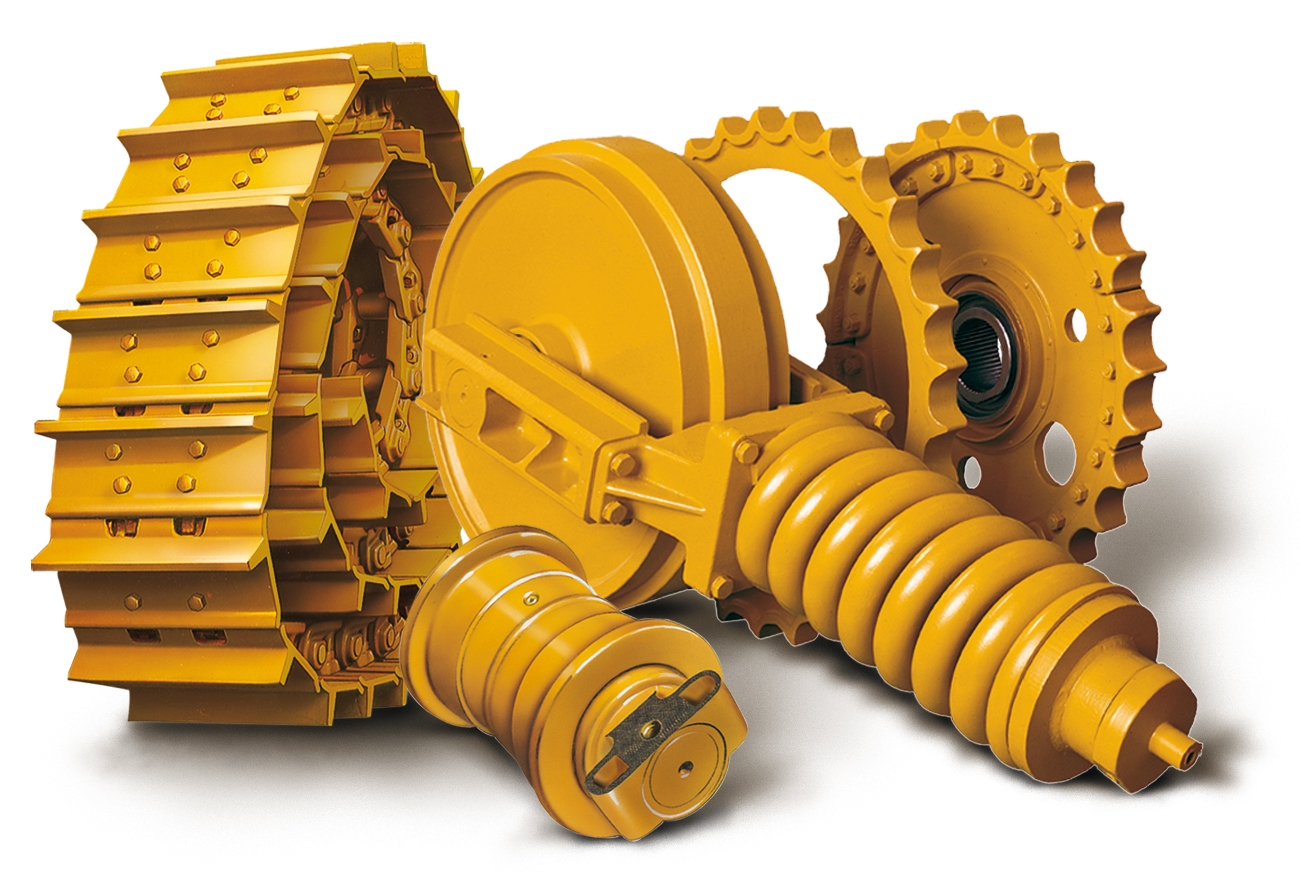

First: maintenance of track roller

I usually see old drivers who are accustomed to the dirt on the track roller. It seems that they are a bit unaccustomed to seeing which pilot is carefully cleaning the mud! In fact, in the daily construction process, in summer, the rollers must be waded in water and soaked in the soil. If this is not avoided, the mud, sand and gravel must be carefully cleaned after work stops, so that the unilateral crawler can be supported. Use the strength of the drive motor to get rid of impurities.

In winter, the seal between the roller and the shaft is most afraid of icing, scratches and oil leakage, so you must pay special attention to this aspect.

Second: the use of carrier roller

To put it simply, if there is a problem with the sprocket, the excavator track will definitely not go straight, so the most basic maintenance work for the sprocket is to prevent oil leakage.

Basically, the oil spill of the carrier roller can only be replaced directly, but the price of a carrier roller is not cheap, so pay more attention to the cleanliness of the X frame of the excavator, and clean up the soil and sand in time. You will find the service life of the carrier roller is effectively increased!

Third: the use of idler

To put it bluntly, except for the fact that there will be incorrect operating habits or brute force operations during use, the frequency of replacement is not high, but it does not mean that it will not be broken!

Therefore, in the process of driving the excavator, ensuring that the idler is in the front can reduce more wear, and the tension spring can also reduce the impact of the ground and reduce the wear of the guide idler.

Fourth: the use of driving sprocket

The drive sprocket is directly fixed on the X frame. It does not have the function of shock absorption. Therefore, the correct operation of the drive sprocket can be ensured when going downhill or walking, which can effectively reduce the wear on the drive teeth and chain rails.

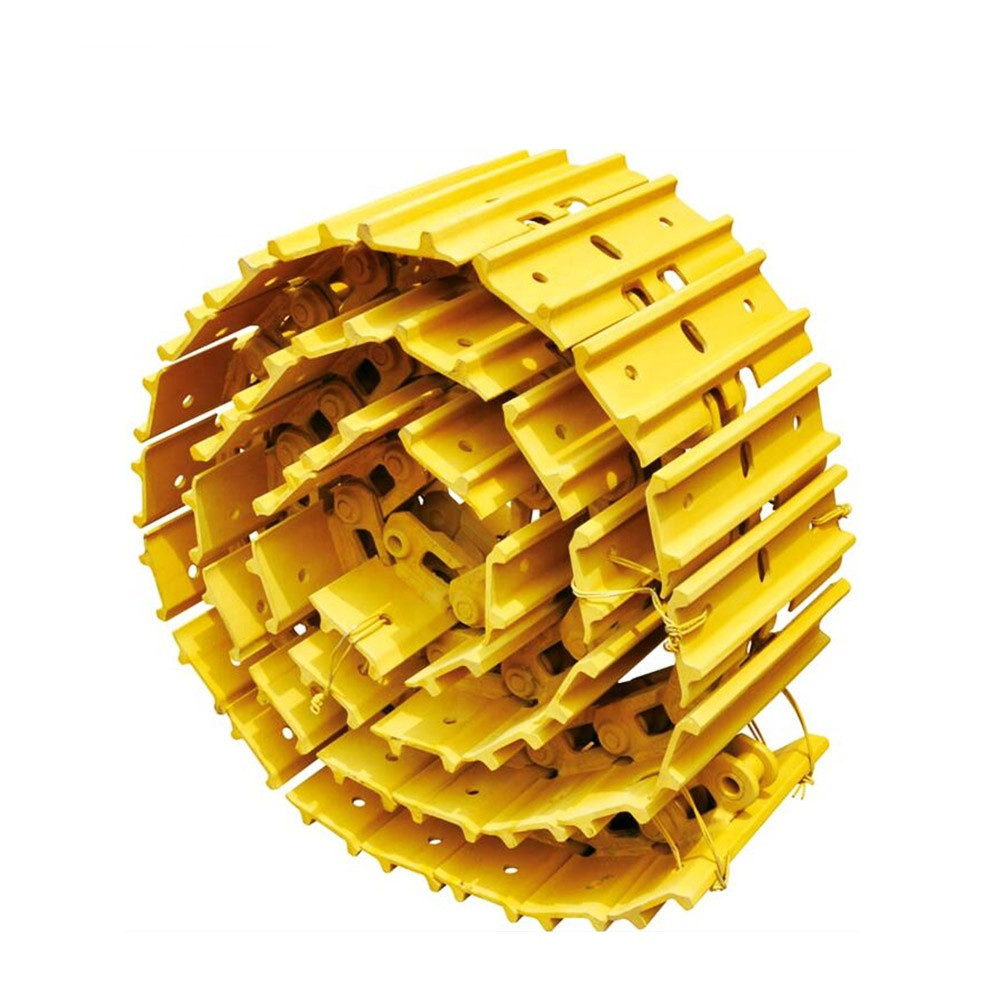

Fifth: Use of track group

Two track groups are equivalent to human shoes, so proper adjustment of the tension is very important, especially everyone should adjust the tension of the crawler according to different working conditions such as wetland, earthwork or mine, so as to effectively increase the life of the crawler.

Focus on mine construction. Under normal circumstances, mine construction is the most worn condition of the crawler. Therefore, it is necessary to clean up the rubble in time after the work is stopped. In addition, after walking for a long time, be sure to check the bending of the crawler board. The degree of deformation and whether the bolts are loose.

If you have the conditions, you can equip the whole excavator with wear-resistant track shoes, the effect is very obvious!

Summarize

In fact, the undercarriage parts are an indispensable part of the whole excavator, and it is also a component that needs more attention from the owners, good operating habits and correct maintenance methods, in order to save more maintenance costs!

Post time: Dec-04-2021