Talking about “four wheels and one belt” refers to Sprocket, idler, track Roller, carriager Roller and belt refers to the track.

They are directly related to the working performance and walking performance of the excavator, and their weight and manufacturing cost account for a quarter of the manufacturing cost of the excavator.

Four round belt, which is briefly described as follows:

Four wheel refers to the wheel drive wheel, guide wheel, support wheel, supporting wheel

The belt refers to the working performance and walking performance of crawler relationship excavator

caterpillar

Classification: There are two kinds of integral and combined.

The integrated track is a track plate with meshing teeth, the trend is meshing with the driving wheel, and the track plate itself becomes the rolling track of the supporting wheel and other wheels.

Features: Easy to manufacture, but wear fast.

The characteristics of the combined excavator are that the pitch is small, the rotation is good, and the walking speed of the excavator is fast. Long service life.

The material used for the track plate is mostly light weight, high strength, simple structure and cheap rolled plate. There are single tendons, double tendons, three tendons and so on.

The excavator mostly uses three tendons. The characteristics are: the height of the tendon is small, the strength of the track plate is large. Smooth movement, low noise.

Track Shoe

There are usually four connecting holes in the track plate, and two mud clearing holes in the middle, which are used to remove clay automatically.

There is a lap between the two track plates which are close to each other to prevent any damage caused by rocks sandwiched between them.

The excavator on the wetland can use a triangular track plate, whose cross section is triangular, which can compress the soft ground and improve the supporting capacity.

Sprocket

The power of the hydraulic excavator engine is transmitted to the caterpillar through the walking motor and the driving wheel, which requires the correct engagement between the driving wheel and the track chain of the caterpillar.

Smooth transmission and good engagement when the track is elongated due to wear of the pin sleeve.

The driving wheel is usually located at the rear of the excavator walking device.

According to the structure can be divided into: integral type, split type

According to pitch can be divided into: equal pitch, unequal pitch

Material: 50MN, 45SIMN, and make its hardness up to HRC55-58

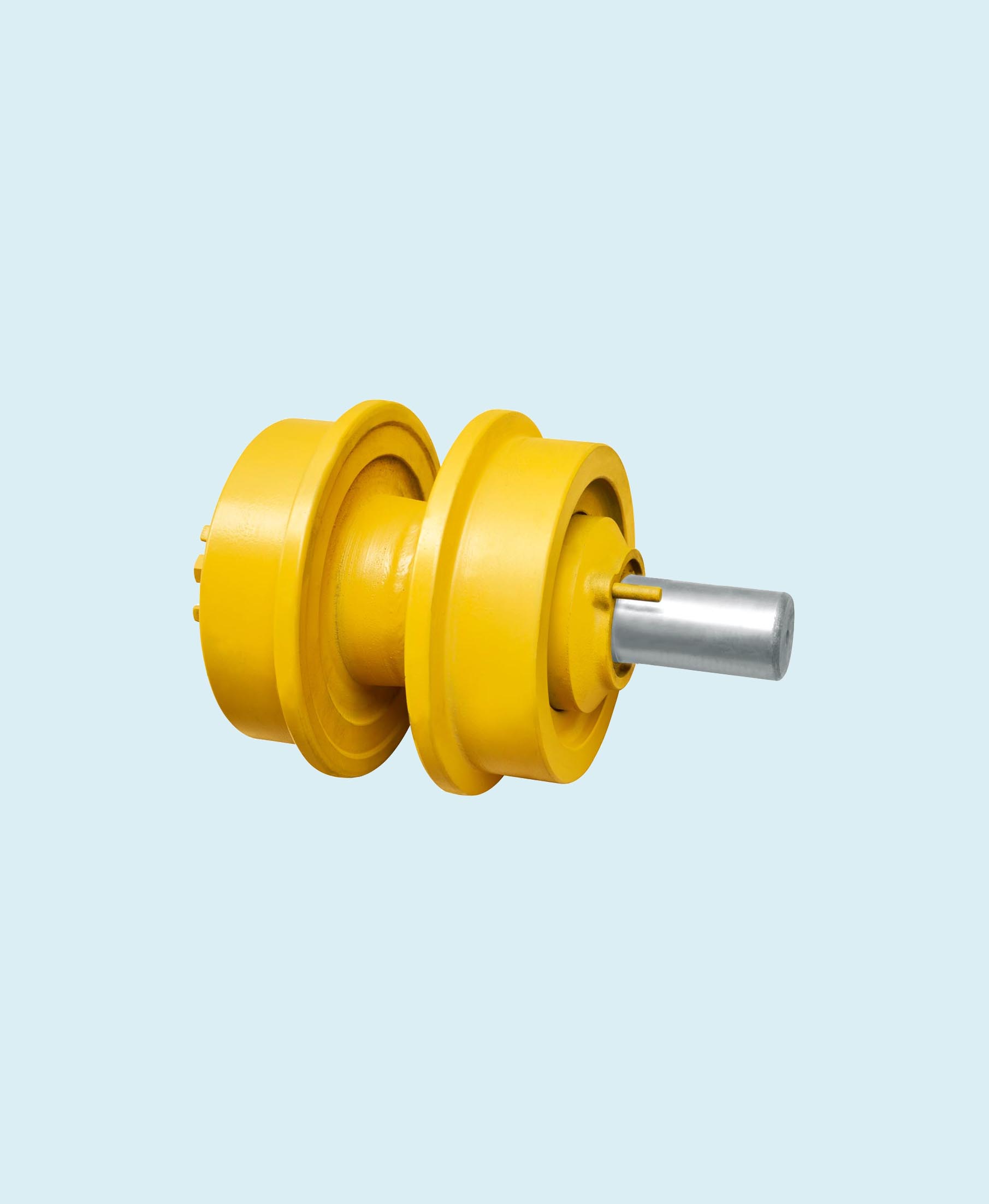

Track Roller

The function of the supporting wheel is to transfer the weight of the excavator to the ground. When the excavator runs on the uneven road, the supporting wheel will be impacted by the ground impact.

Therefore, the load of the heavy wheel is large, the working conditions are bad, often in the dust, and sometimes soaked in mud, so it requires a good seal.

Material: mostly 35MN, and 50MN. The wheel surface is quenched and the hardness reaches HRC48, 57 to obtain good wear resistance.

The use of sliding bearing support. And floating oil seal dust.

During an overhaul period, butter is generally added once, which simplifies the usual maintenance work of excavators.

Idler

The guide wheel is used to guide the track around correctly and prevent it from running off course and off track.

Most excavators also play the role of a heavy wheel. This can increase the track to the ground contact area, reduce the ground pressure.

The wheel face of the guide wheel is made of smooth surface, and the middle arm ring serves as a guide, while the torus on both sides supports the rail chain.

The smaller the distance between the guide wheel and the nearest support wheel, the better the steering.

Material: 40,50 steel, or 35MN, cast, tempered and tempered, hardness HB230-270

Key points:

In order for the guide wheel to function and extend its life, the radial runout of the wheel facing the center hole should be less than or equal to 3MM, and should be properly centered when installed.

Carrier Roller

The function is to hold the track up, so that the track has a certain degree of tension.

Post time: Nov-02-2022