D6D Bulldozer Front Idler assembly

Product Description

The excavator track idler surface of the guide wheel is a smooth surface, and there is a retaining arm ring in the middle as a guiding function, and the ring surfaces on both sides support the guide rail chain.

The main points of the excavator guide wheel:

In order to make the excavator guide wheel work normally and prolong its service life, the radial runout of the center hole of the wheel should be less than or equal to 3MM, and it should be correctly aligned during installation.

The bulldozer front idler assembly adopts the box structure cast by resin sand process. The appearance quality of the wheel body has reasonable mechanical structure performance. The matrix is normalized to obtain good impact resistance, and the medium frequency induction quenching heat treatment of the track surface. Surface hardness To hrc48-54, the depth is not less than 6mm, with wear resistance in harsh conditions

ILDER: forged material (40Mn/35SiMn)

Depth: 6mm (Shaft1.5-2mm) Hardness: HRC48-54

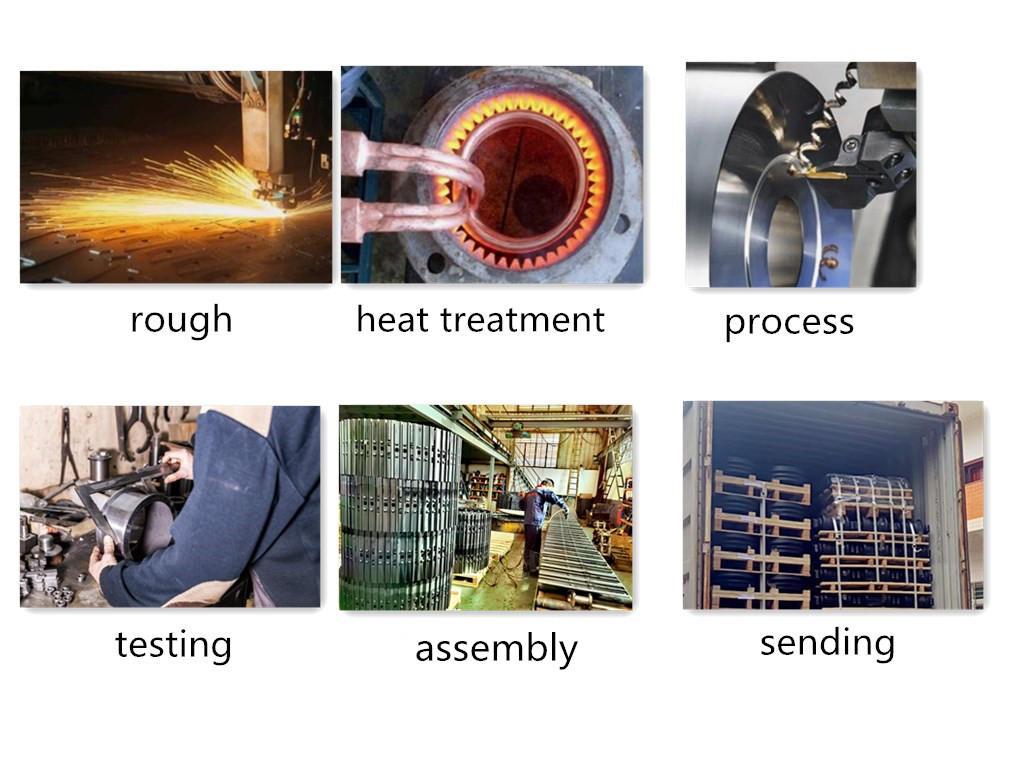

IDLER body: forging - turning - quenching - fine turning - pressure bushing - welding slag shovel (cleaning the surface of the machine body)

| Material | 40Mn/35SiMn | |

| Finish | Smooth | |

| Technique | Casting/Forging | |

| Surface Hardness | HRC52 , Depth6mm | |

| Colors | Black or Yellow | |

| Warranty Time | 1440 Working Hours | |

| Certification | IS09001-9001 | |

| MOQ | 2 Pieces | |

| FOB Price | FOB Xiamen US$ 50-200/Piece | |

| Delivery Time | Within 30 days after contract established | |

| Payment Term | T/T,L/C,WESTERN UNION | |

| OEM/ODM | Acceptable | |

| type | bulldozer undercarriage parts | |

| Moving Type: | Crawler bulldozer | |

| After-sales Service Provided: | Video technical support, Online support |

We all use the best 40Mn/35SiMn steel as raw materials, and use differential quenching to increase the hardness of the idler , increase the wear resistance of the idler , and delay the wear of the dozer idler wheel body.

Packing and shipping