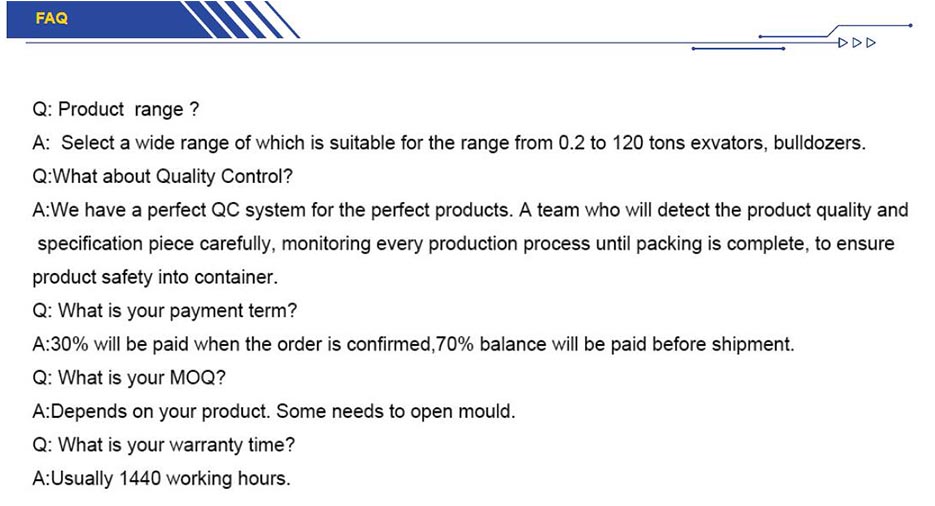

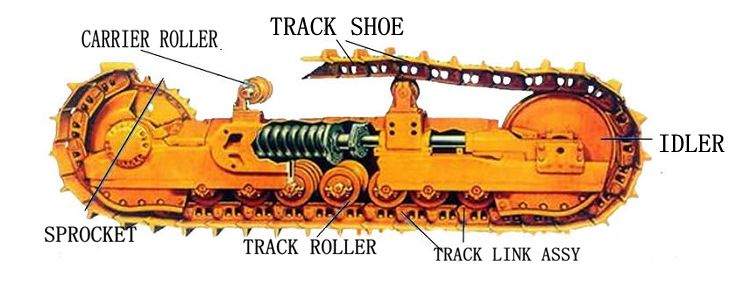

Mini Crawler Excavator and Bulldozer Sprocket Zax330 Undercarriage parts

Product Description

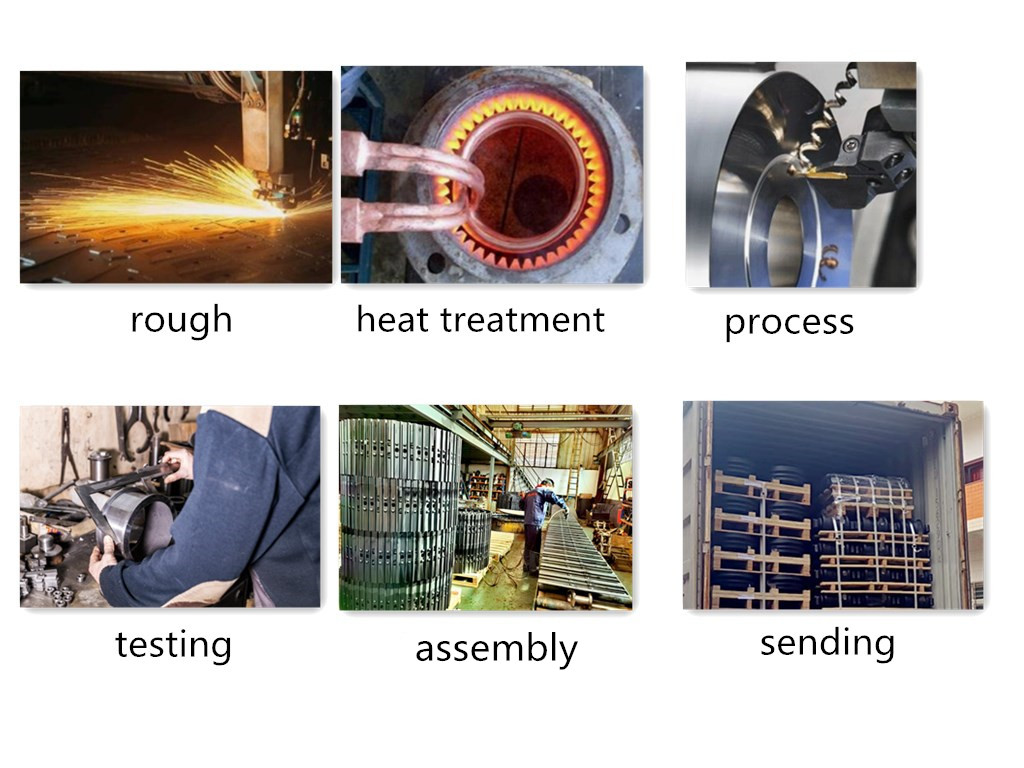

Through professional quench-tempering processes to guarantee excellent mechanical properties, high strength and superior wear resistance to bending and breakage .

Produced in advance machining center and vertical CNC turning machine for precision requirements. Surface hardness HRC 42-56 for reduced wear and longer life, adding value to your products future to your business by maximizing durability of your products. 100% quality assurance, develop and manufacture follow or even exceed original ones.

1.Material :Alloy Steel, Carbon Steel, Stainless Steel, Hardend & Tempered Steel , Cast Iron , Aluminum ,Copper, Brass and so on.

2.Heat Treatment :Hardening and Tempering, high frequency quenching, Carburizing Quenching and so on.

3.Inspection ;All items are checked and tested throughly during every working procedure and after the product is finally manufactured to ensure that best quality product goes out in the market.

4.Durable, good wear resistance.

| Material | 40Mn/35SiMn |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC55 , Depth6mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T, L/C |

| OEM/ODM | Acceptable |

| type | bulldozer or excavator undercarriage parts |

| Moving Type: | Crawler bulldozer |

| After-sales Service Provided: | Video technical support, Online support |

We are using advance machining centre, horizontal and vertical CNC machining to execute processes such as machining, drilling, threading and milling to ensure the quality and precision of each component to ensure th accuracy of assembly dimensions. This is to maximize the life span of each component to ensure the accuracy of assembly dimensions. This is to maximize the life span of each component and minimize production cost per hour.

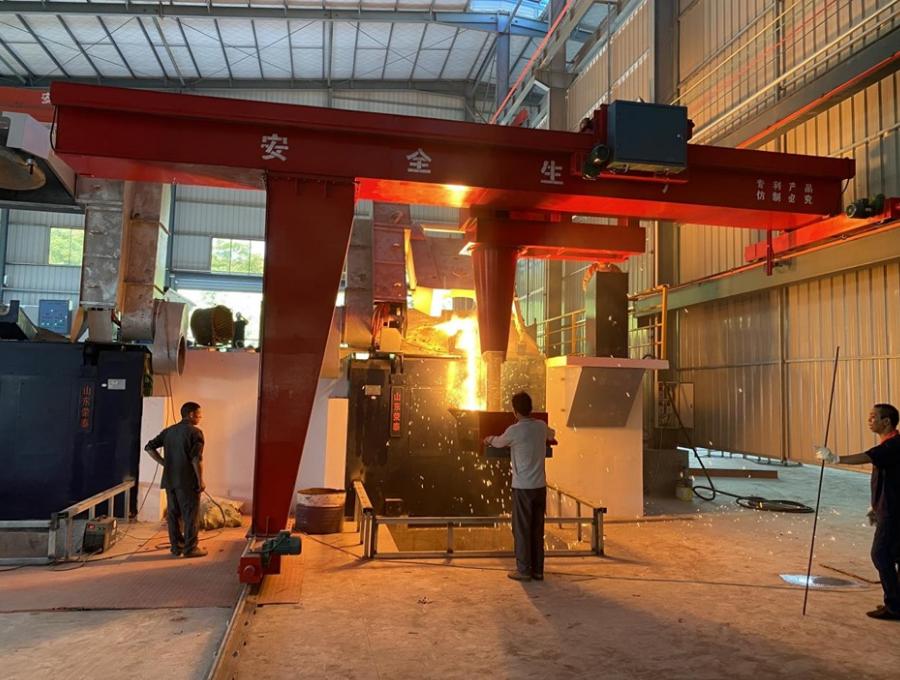

We have our own processing plant and foundry to show you the best quality

Packing and shipping

Exhibitions over the years