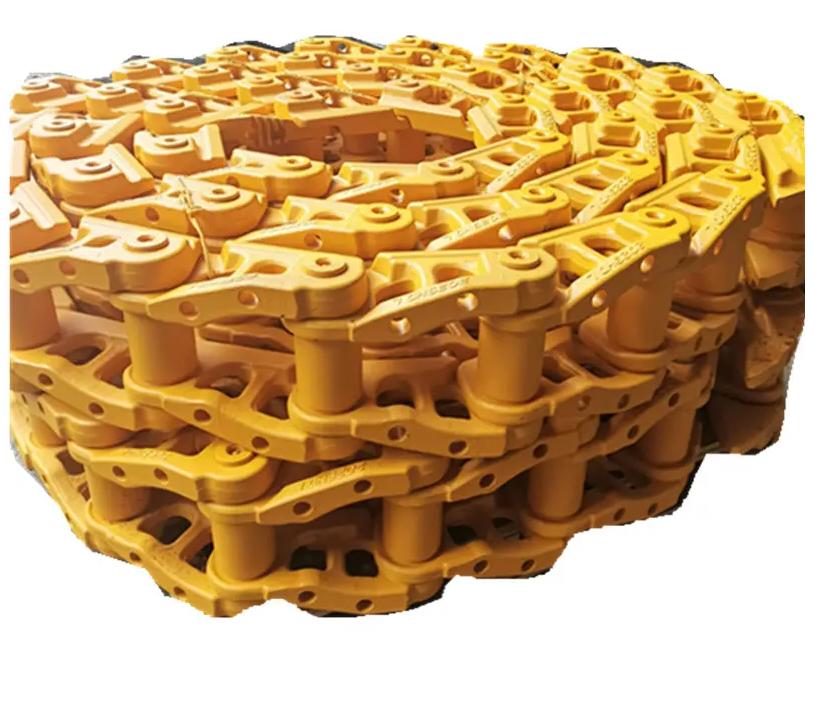

D6T track chain 45L

Product Description

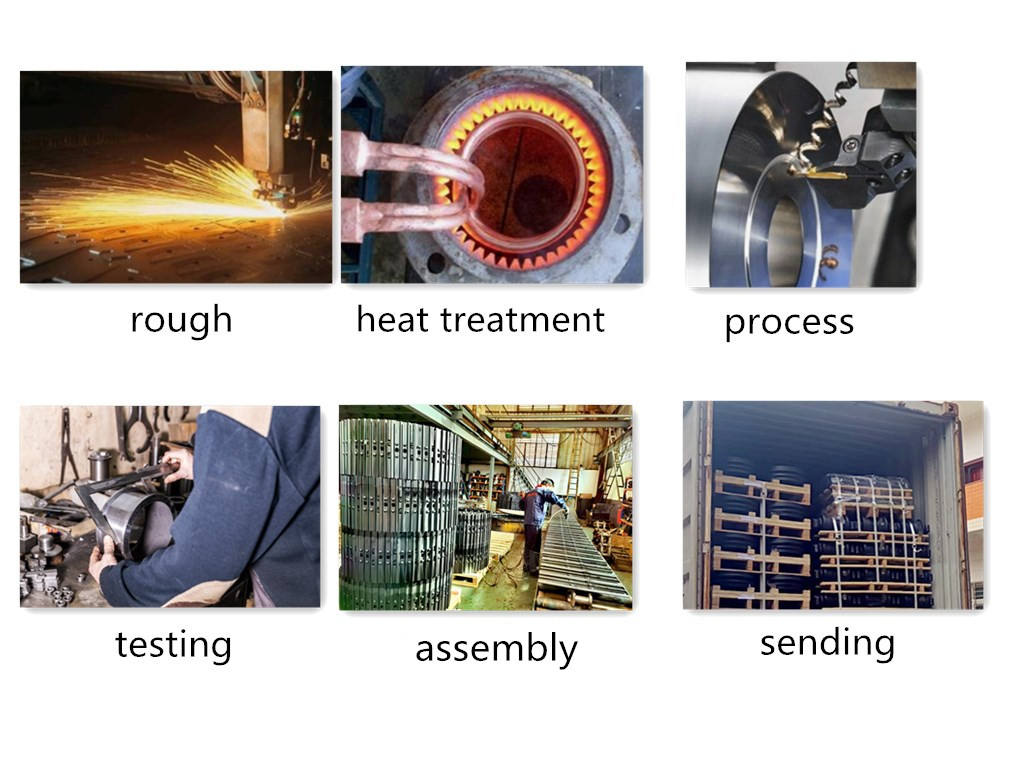

We treat the various components of the track chain assembly to increase its wear resistance and hardness. To make sure it lasts longer in a variety of terrains, we'll temper it to make it even and finer inside. Make the hardness reach HRC55. Through quenching and differential quenching are adopted, and then quenching is repeated until each part reaches the standard hardness

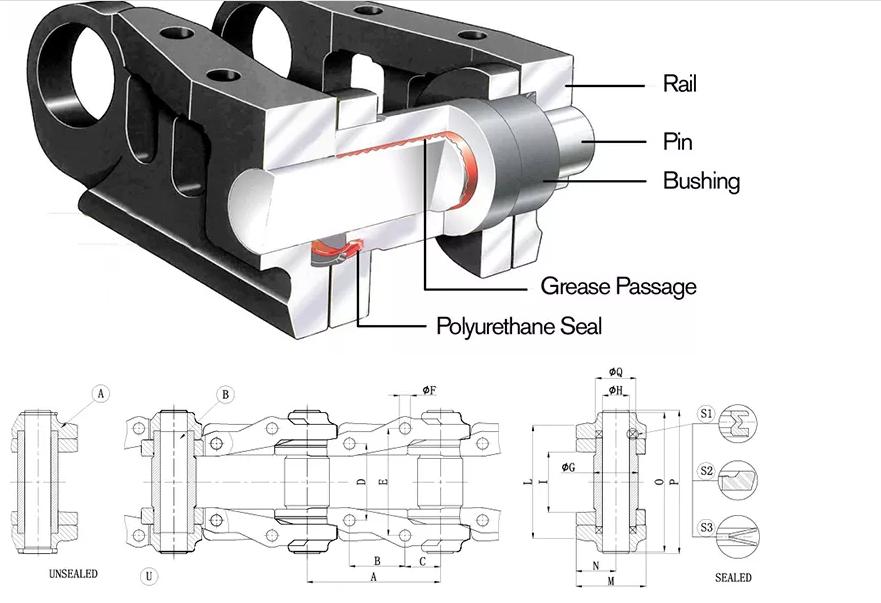

The following chart shows the model range and

parameters that Excavator track chain can be made.

S shows the different sealing forms of the

excavator chain seal model.

S1 = Steel Spacer

S2 = TPU Spacer

S3=M Seal

track chain: forged material (45MNb)

Depth: 3mm (Shaft1.5-2mm) Hardness: HRC55-60

track chain: forging - turning - quenching - fine turning - pressure bushing - welding slag shovel (cleaning the surface of the machine body)

Shaft Forging Turning Operation Drill Tapping Quenching and Tempering Grinding

Carrier Roller Parts: Test Paint Check Storage

| Material | 45Mnb | |

| Finish | Smooth | |

| Technique | Casting/Forging | |

| Surface Hardness | HRC56 , Depth10-12mm | |

| Colors | Black or Yellow | |

| Warranty Time | 1440 Working Hours | |

| Certification | IS09001-9001 | |

| MOQ | 2 Pieces | |

| FOB Price | FOB Xiamen US$ 25-100/Piece | |

| Delivery Time | Within 30 days after contract established | |

| Payment Term | T/T,L/C,WESTERN UNION | |

| OEM/ODM | Acceptable | |

| type | bulldozer undercarriage parts

|

|

| Moving Type: | Crawler bulldozer | |

| After-sales Service Provided: | Video technical support, Online support |

We all use the best 45mnb steel as raw material, and use differential quenching to increase the hardness of the track chain assembly, increase the wear resistance of the track chain and the hardness and wear resistance of the chain, and delay the wear of the track chain body.

application

excavator

Bulldozer

Packing and shipping

ABOUT US

Fujian Jinjia Machinery Co.,Ltd. is developing from Quanzhou Hongda Machinery Co.,Ltd. The company has dedicated to the manufacturing of crawler undercarriage parts since 1990, which has been more than 30years so far. Now we have established our own casting, forging and machining production centers.

JINJIA Machinery has always been insisting on the operation policy of “Customer first, Quality first” . Our mission is to make customer satisfaction. Just because of this, these years the company has obtained high reputations and solid foundation in the machinery industry. Today our production scales have been constantly expanding, with a wide range of product categories. Our products have been popular in domestic markets as well as the international markets such as Europe, America, South East of Asia, Middle East, etc. We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

Exhibitions over the years

FAQ

Q: Product usage?

A: If any problem about usage, I will solve at first time.

Q:What about Quality Control?

A:We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.