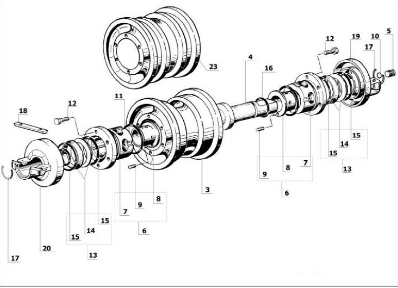

Heavy equipment crawler crane KH180-3 bottom track roller parts 50T for HITACHI

Product Description

The design of double cone seal and lifetime lubrication makes the rollers have a long life and perfect performance under any working conditions

The hot forged wheel housing can obtain better hardness, and the differential quenching can improve the crack resistance of the roller

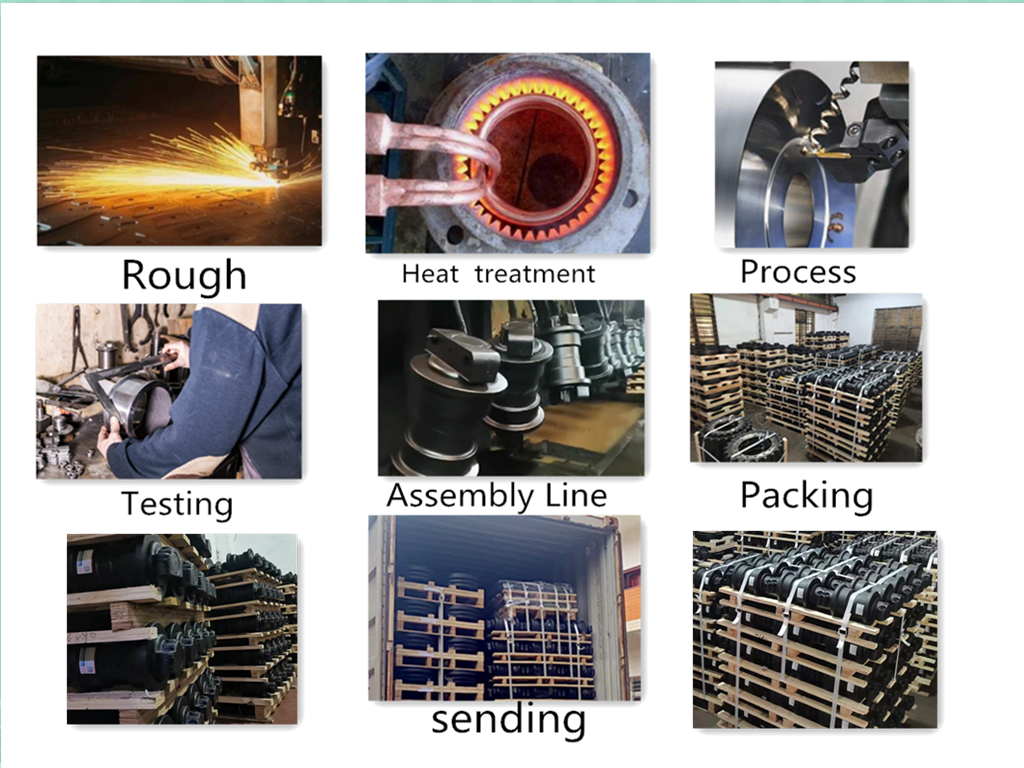

End cover :forging/casting/steel rod-rough and fine turning operation drill tapping

All parts ready to: assembly-Pressure Test Filling Oil Spray Paint Checking Storage

| Material | 50Mn |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC55-60 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

The roller body we choose is 40Mn2 mainly by casting and forging. It is finished by CNC machine tool and then heat treated, so that the hardness of the wheel surface after quenching can reach hrc50, in order to improve the wear resistance. In terms of precision, we choose the most advanced CNC machine tools, in order to produce the best products

Application

Packaging & Shipping

Our advantage

Dedicated to the manufacturing of undercarriage parts for 50years, wide range of product categories are available.

These years, we have established our own steel & iron casting factory, forging and machining production centers. Quality is controllable from raw material to the whole production processes.

R&D teams are available in house.

Quality Guarantee: Advanced inspection instruments and experienced QC team ensure high controls from raw material to production and shipment. Quality controls and quality shipment!

Exhibitions over the years

ABOUT US

Fujian Jinjia Machinery Co.,Ltd. is developing from Quanzhou Hongda Machinery Co.,Ltd. The company has dedicated to the manufacturing of crawler undercarriage parts since 1990, which has been more than 30years so far. Now we have established our own casting, forging and machining production centers.

JINJIA Machinery has always been insisting on the operation policy of “Customer first, Quality first” . Our mission is to make customer satisfaction. Just because of this, these years the company has obtained high reputations and solid foundation in the machinery industry. Today our production scales have been constantly expanding, with a wide range of product categories. Our products have been popular in domestic markets as well as the international markets such as Europe, America, South East of Asia, Middle East, etc. We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

FAQ

If there are details that cannot be handled, can anyone help?

Of course, if you have any questions about use, you can contact our customer service, our customer service will be enthusiastic to help you solve the problem

Which instant messaging software do you support?

We currently support wechat skype WhatsApp qq and so on